top of page

Search

How Corrosion Impacts Commercial HVAC Systems (And How to Prevent It)

Discover how Commercial HVAC Corrosion impacts efficiency and lifespan. Learn prevention strategies to protect your HVAC system from corrosion.

Krystal Morrell

2 days ago4 min read

Preparing Your Commercial HVAC Coils for This Weekend’s Hard Freeze

Prepare your Commercial HVAC system for a big freeze. We've got tips to protect your coils, prevent failures, and keep your systems running. Learn what to check before the cold hits and. who to call if you experience a coil emergency.

Krystal Morrell

Jan 193 min read

The Biggest Coil Myths We Hear Every Week

Discover the truth behind common Coil Myths in HVAC systems. Learn how Re-Coil debunks Coil Myths and offers solutions for your system's needs.

Krystal Morrell

Nov 24, 20252 min read

What You Need to Know Before Ordering a Commercial Replacement HVAC Coil

Discover what you need to know before ordering Commercial Coil replacements in order to avoid costly mistakes. Learn how Re-Coil Solutions onsite measurement can help you get the perfect fit the first time.

Krystal Morrell

Oct 20, 20253 min read

Retrofit vs. Replace: Making the Right Call for Aging HVAC Systems

Explore the cost-effective benefits of Retrofitting HVAC Coils instead of replaced entire systems. Discover how retrofitting can extend your equipment's life and efficiency without breaking the bank.

Krystal Morrell

Aug 14, 20252 min read

When the Waters Rise: Protecting and Restarting Commercial HVAC Systems After Flooding

Discover expert tips for safeguarding and restarting Commercial HVAC systems after flooding. Learn how to protect against Commercial HVAC Flooding.

Krystal Morrell

Aug 7, 20253 min read

How U.S. Tariffs Are Set to Impact HVAC Pricing- And What you Can Do About It

Discover how U.S. Tariffs are impacting HVAC costs. Learn strategies to mitigate rising HVAC pricing and protect your investments.

Krystal Morrell

Apr 28, 20253 min read

The HVAC Industry Faces Uncertainty Amid Regulatory Shifts: Refrigerant Transition On Pause?

Explore how the HVAC industry's refrigerant transition faces uncertainty amid regulatory shifts.

Krystal Morrell

Mar 17, 20252 min read

Re-Coil Solutions: Setting the Standard in HVAC Coil Replacement & Customer Service

Top-notch Replacement HVAC Coil solutions at Re-Coil Solutions. Experience precise onsite service measurement and customer service today!

Krystal Morrell

Feb 17, 20252 min read

Re-Coil Solutions Achieves USFCR Certification: What It Means for You

Discover how Re-Coil Solutions' USFCR Certification benefits you. It is not easier than ever to secure a contract with government agencies.

Krystal Morrell

Jan 20, 20252 min read

Navigating the 2025 HVAC Refrigerant Transition: What You Need to Know

Prepare for the 2025 Refrigerant Transition with essential info on new refrigerants, safety standards, and tips for a smooth shift.

Krystal Morrell

Nov 21, 20245 min read

Top Benefits of Using Chilled Water Coils for Efficient HVAC Cooling

Discover the top benefits of using Chilled Water Coils for efficient HVAC cooling.

Krystal Morrell

Sep 19, 20245 min read

Back to School in Sweltering Heat: The Double-Edged Sword of Green HVAC Regulations for Aging U.S. Schools

Discover how US Schools are facing challenges in meeting new energy regulations and the financial burden of upgrading outdated systems.

Krystal Morrell

Aug 22, 20243 min read

The Impact of Prolonged Power Outages on Commercial HVAC Systems and Prevention Strategies

Discover the crucial impact of prolonged power outages on commercial HVAC systems and effective prevention strategies.

Krystal Morrell

Jul 15, 20243 min read

Top Reasons Your Commercial HVAC Coils Freeze in Summer and How to Prevent It

Discover the top reasons why HVAC coils freeze in summer and how you can prevent it. Learn valuable insights and effective solutions.

Krystal Morrell

Jun 18, 20247 min read

The Economic of Efficient HVAC Systems: A Cost-Benefit Analysis for Businesses

Upgrade your HVAC system with efficient coils for substantial long-term savings. Learn about cost-benefit analysis and available rebates.

Krystal Morrell

May 13, 20244 min read

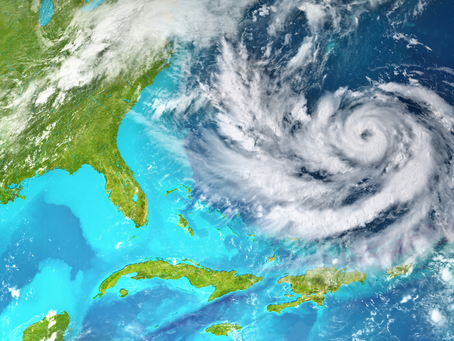

Weathering the Storm: Preparing Commercial HVAC Units for Hurricane Season

An Active Hurricane Season Approaches As hurricane season approaches, businesses across coastal regions brace themselves for the...

Krystal Morrell

Apr 18, 20243 min read

Spring Cleaning for Your Commercial HVAC System: Preparing Coils for Summer Efficiency

As the vibrant hues of spring emerge, it's not just the flowers that need a refresh – your commercial HVAC system does too! With summer...

Krystal Morrell

Mar 7, 20243 min read

Boost Your HVAC Efficiency: The Benefits of Converting from Microchannel Coils

Converting a microchannel coil in a commercial HVAC (Heating, Ventilation, and Air Conditioning) unit may seem like a specialized task,...

Krystal Morrell

Feb 26, 20243 min read

The Chilling Truth: How Freezing Weather Impacts Commercial HVAC Coils

Introduction: As winter blankets the landscape in a glistening coat of ice and snow, commercial HVAC systems face a formidable adversary...

Krystal Morrell

Jan 18, 20243 min read

Re-Coil Solutions Blog

bottom of page